With natural selection, organisms that best adapt to their environment have the highest chance of survival.

The same is true in business, especially for RB Digital.

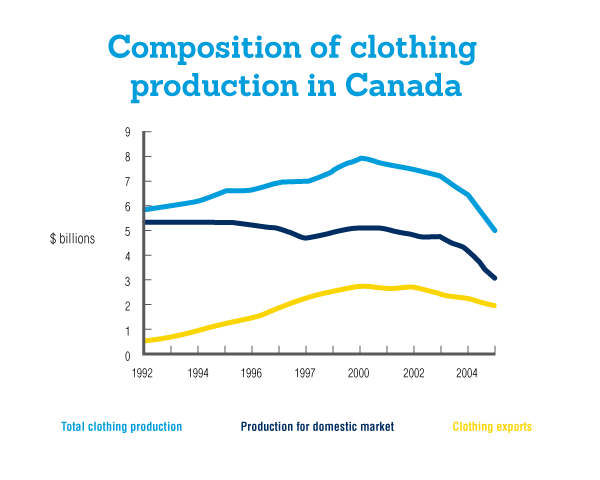

Before the late 1990s, most of RB Digital’s business came from selling industrial sewing machines to national clothing manufacturers, but as Canada gradually removed duty on clothing imports, domestic production dwindled. Canadian companies couldn’t match international competitors that reaped benefits from low-cost labour.

RB Digital faced a choice: struggle to continue selling apparel equipment to Canada’s apparent moribund apparel production industry or adapt to survive.

RB Digital: a history of adaptation

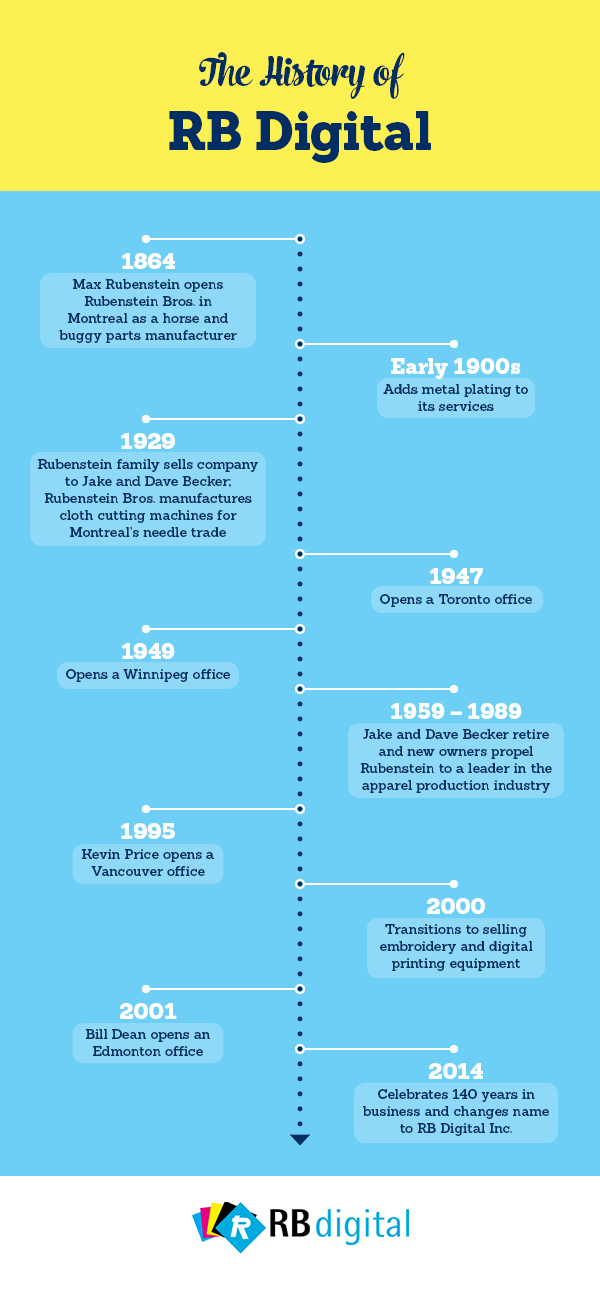

There’s a reason RB Digital has been around longer than Canada has officially been a country. It welcomes change.

“Adaptations aren’t uncommon for the company,” said Kevin Price, President of RB Digital. “The company started in 1864 selling parts for the horse and buggy trade.”

When the automobile raced into the transportation industry, RB Digital reined in its horse and buggy parts business and shifted to modern metal work. It manufactured cloth cutting machines, electrical intersections for Montreal’s streetcars and, during World War II, produced landing gear parts for the Royal Canadian Air Force. The company eventually entered the garment business, experiencing impressive growth that propelled Canada-wide expansion.

Growth through innovation

Back to the early 2000s. With Canada’s borders open to duty-free clothing imports, domestic apparel production plummeted. Two things became apparent: Canadians didn’t want to spend more money on domestic clothing when cheaper alternatives were available and RB Digital’s strategy to sell manufacturing equipment couldn’t last.

But RB Digital noticed something interesting: the Canadian clothing industry wasn’t dying. It was evolving. Domestic clothing companies were no longer producing apparel; they were customizing it. And if the popularity of the automobile thrust RB Digital into the 20th century, the shift to digital printing nudged it into the 21st. The company adapted yet again and started selling the latest wide-format printing, direct-to-garment and industrial embroidery equipment.

Adaptation is a challenge

When the company primarily sold industrial sewing machines, the most expensive machine could cost around $2,000. Digital printers and embroidery machines can cost over 25 times that amount.

To keep equipment acquisition financially viable for its customers, RB Digital offers leasing through CWB National Leasing. Instead of tying up cash or lines of credit with an upfront payment, equipment leasing spreads the equipment cost over years.

“Our customers generally cover their payment within the first week of the month when they lease their equipment,” said Kevin. “The equipment generates enough money to pay for itself.”

RB Digital works closely with CWB National Leasing Account Manager, Jenny O’Callaghan, whom Kevin considers as more than just a liaison.

“Jenny is our partner in the sales process. She’s dependable, she’s a good personality to work with customers, and she adds value to our sales strategy rather than just parallels it.”

A thriving partnership

The partnership has been a boon for RB Digital. The company is projected to sell over $1 million worth of equipment through leasing in 2015, a 500 per cent increase from last year’s lease sales.

“Working with RB Digital is a true partnership,” said Jenny. “Kevin’s team really promotes leasing and involves me in trade shows and events. He may even tease that I work for RB Digital!”

Kevin can’t be certain of RB Digital’s future, but if the company’s 150-year history is an indication, surely it will adapt yet again.

- Share

Financing made easy.

Contact us and we'll call you right away